In-house or outsourced 3D printing? Pros and cons.

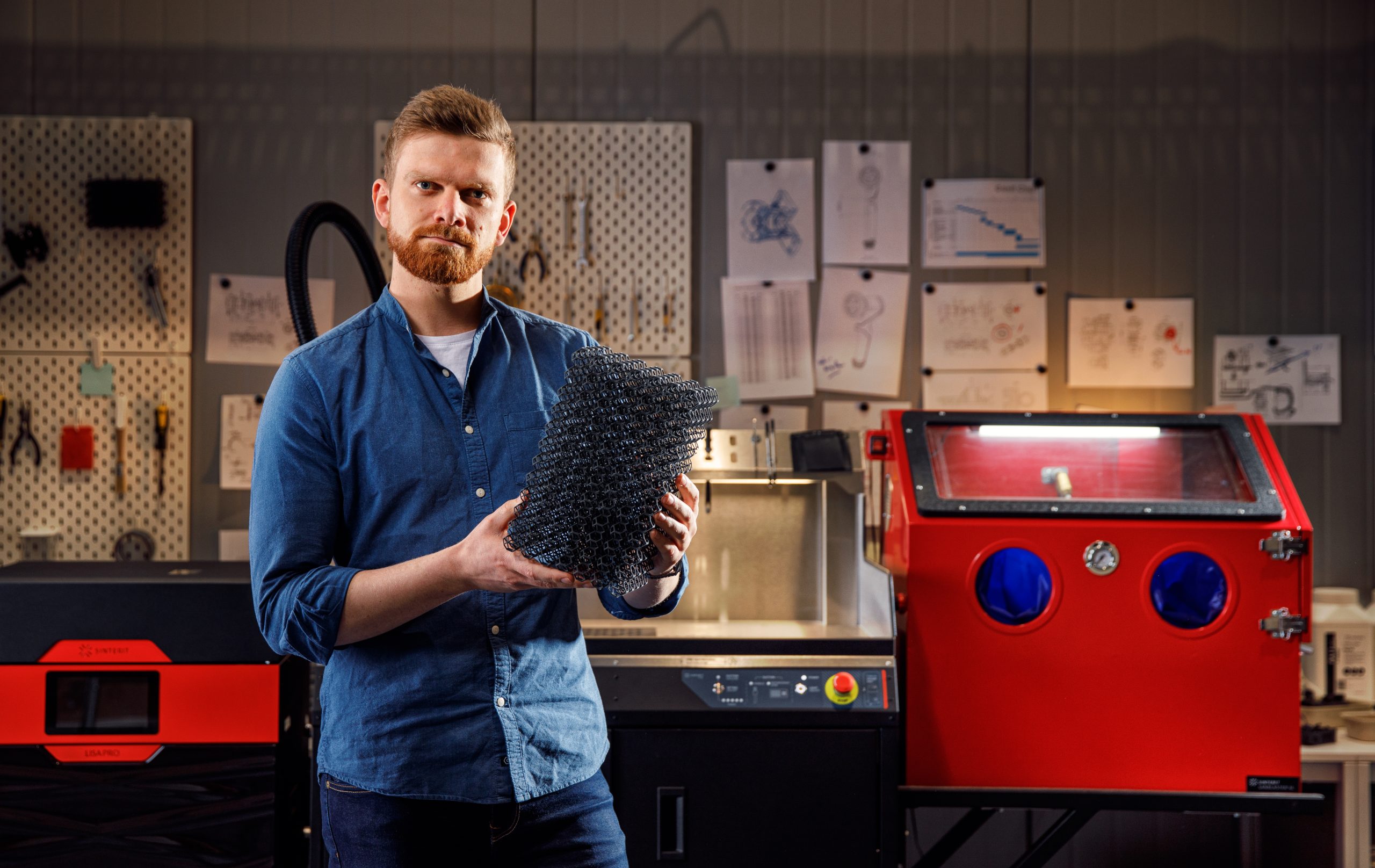

Purchasing a professional 3D printer is always an investment that should be carefully calculated. SLS 3D printing technology has become more accessible, and buying printers such as Lisa X from Sinterit is getting within the reach of companies that couldn’t afford it before. What are the reasons you should consider when deciding whether to buy your 3D printer or outsource your 3D printing needs?

We have listed 10 benefits of in-house 3D printing and also 10 of using service providers. Let’s find out which one fits you better.

Why should I invest in the 3D printer?

#1 Cost-effectiveness

The first reason is strictly financial. Owning professional 3D printers is associated with a rather high initial investment. For decades it was almost impossible for small and medium companies to purchase SLS 3D printers, as the price started from more than 100k EUR per unit. When compact SLS solutions hit the market in 2014, prices dropped even 20 times for basic SLS 3D printers. As for 2024, professional compact SLS 3D printers are still several times more affordable than their industrial-grade counterparts.

But still, you need to use your printer regularly to achieve the best ROI and cost-effectiveness you are looking for in the first place. With every additional 3D printing job and element printed, the cost per print decreases. You also don’t pay any service fee.

#2 Shorter lead time

Owing 3D printers makes you more agile, which is a credo of 3D printing. An in-house 3D printer gives you control over the production schedule. If your design is ready, just hit the button and start 3D printing right away. No additional communication with third-party companies is needed. You also don’t have to wait for an available free spot to print your parts.

#3 Faster iterations

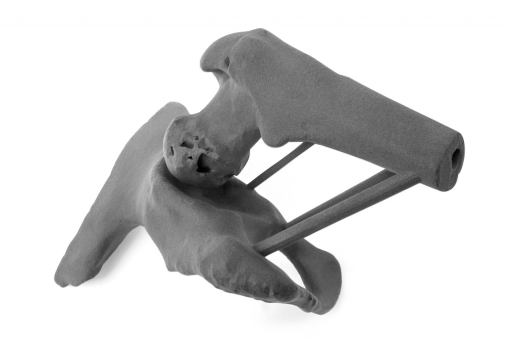

Especially during the prototyping phase, you will probably need a bunch of modifications made to your design. One of the biggest benefits of 3D printing invention is that you can develop your ideas through trial and error methods.

You don’t have to spend hours on your design software to draw perfect, errorless products. This is not theoretical mathematics. 3D printing gives you the option to make iterations, observe your product in real use, adjust, and achieve the best possible outcome in a relatively short time.

Choosing an external provider for each iteration will make this process longer.

#4 Security

Confidentiality is one of the reasons usually added to the list of benefits for 3D printer owners. But we would like to make it clear: professional service developers will sign NDA contracts with you so are also protected.

But of course, when more people and companies are engaged in projects, the risk of property theft and leakage may be greater. It is especially visible in specific sectors as the military. The security level is increased to such an extent that the printer cannot be remotely connected to the network or other devices in any way, to prevent hacking attempts.

#5 Flexibility

Life shows that many inventions were born by accident. Do you know how Post-it notes were developed? In 1968 Dr. Spencer Silver was working to develop a very strong adhesive but instead, he created the opposite. It could be considered a failure but Dr. Silver’s colleague, Arthur Fry, found out that it could be used as a bookmark.

Owning a 3D printer gives you a lot of options and freedom to experiment with different materials and printing parameters. So it is especially important when choosing a 3D printing solution, that there is a possibility of changing the printer’s parameters. Remember to ask the producer if the 3D printer has an open architecture or open parameters.

#6 Quality control

It is not a secret that some technologies, like SLS, are chosen because of the printed parts quality. If you are handling the printing process internally, you directly oversee the entire production workflow, ensuring consistent quality and adherence to standards.

#7 Print whenever you want or need

A lot of users streamline their 3D printing to jobs to print by night or through the weekend. Taking advantage of company closing hours makes the workflow better. On the other hand, when you own the printer you can produce parts whenever you need them, without the need to wait for some minimum order or extra production time.

#8 Reduced shipping costs

Owning a 3D printer will reduce all transportation and shipping costs. You don’t have to pay for the delivery of your parts.

#9 Becoming 3D printing expert

The more you print in-house the better you become in operating the printer and knowing the technology, its possibilities, and limitations. With more expertise, it will be easier for you to invent new products.

#10 Coping with emergencies

Owning a 3D printer makes you more agile, as we said before. But let’s look at it in a different context. Some operations need to be done fast to quickly respond to emergencies. In this case, an in-house 3D printer could be a life-saver for your project.

Benefits of outsourcing 3D printing

Outsourcing 3D printing also has its advantages. Some of them are similar to having a printer within the company but differ in slightly different accents and expectations.

#1 Cost savings

If you don’t print a lot or are new to the technology it is good to work with the service provider. No upfront investment in equipment, maintenance costs, or material costs is beneficial. The pay-as-you-go model is good for testing new technologies and printing a small number of parts, especially if there is no hurry.

#2 Best equipment in class

Some service providers have a wide machine range, with a lot of different 3D printing technologies available. You can benefit from it. We know that Lisa X is becoming very popular so it is also a good way to test it and compare it with other 3D printers to decide if you should consider buying it in the future.

#3 Scalability

As always you should calculate costs, but there are situations when you need to scale up very fast. Expanding your own machinery may be difficult or impossible to organize in a short time, and an external supplier will help you respond quite quickly to the increase in demand for your solution.

#4 Don’t worry about the maintenance

It is a tricky benefit because compact SLS 3D printers such as Lisa X don’t need a lot of maintenance and it is easy to perform without any special knowledge, but some bigger solutions need service by a qualified employee of the printer manufacturer.

#5 Fast lead time for regular customers

If you are a regular customer you can benefit from faster lead time and other bonuses which may keep you a client for a longer period. But still, you need to check the ROI.

#6 Focusing on core competencies

Some companies don’t want to educate themselves in new fields such as 3D printing. If you are one of such companies or just don’t have enough time to learn, you can outsource 3D printing. But also remember that some technologies and printers are quite easy to run and understand.

#7 The 3D printing expertise

Service providers print a lot and know the 3D printing technology like no one else. Their knowledge could be compared with internal 3D printing teams that work for each of the 3D printer producers. You can ask them for expertise on the right technology or material for your project.

#8 More materials

Outsourcing 3D printing can also be a good idea if you need to test more materials. Every printer has a limited number of materials. Of course, there are such as Lisa X with an open architecture that gives you the option to test an endless number of printing powders, but they need to meet some requirements and they must fit into the technological capabilities of the printer. The service provider has access to more printers and more materials.

#9 Risk mitigation

Power outages, maintenance downtime, or technology obsolescence can be a problem. The use of a 3D printer provider can mitigate the risk and lower the costs.

#10 Print closer to the client

Companies decide to invest in 3D printing to produce parts close to the market in which they operate. If a large group of your clients or subcontractors live in a remote location from your company it may be wise to connect with the local service provider.

Summary

This article allows you to carefully weigh pros and cons, when considering buying a 3D printer for in-house production. There is no one good scenario for all. The most important thing is to give your company a chance to use the most comprehensive 3D printing technology.