Final car elements with SLS prints of very high strength and resistance

-

showing a design concept redesign as a method to create reliable parts

-

prototype new products creating parts not available on the market

-

perform functional powder materials precisely dedicated to the specific requirements of the parts

Background

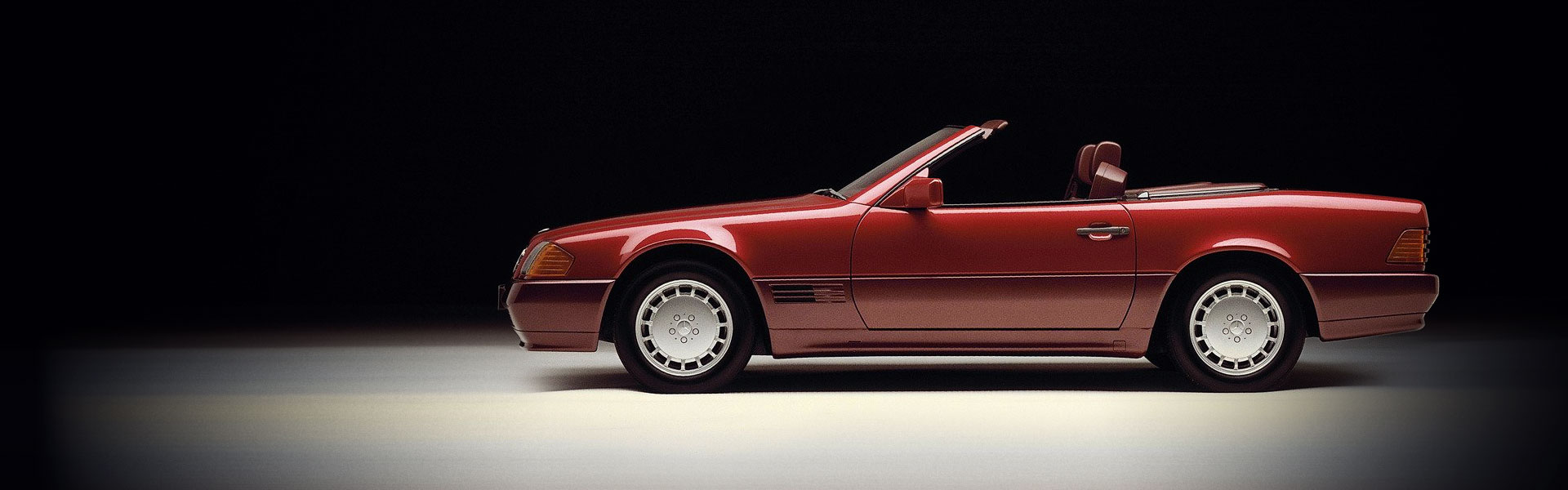

OctoClassic is a company that produces professional spare parts for classic cars. The founders met in 2019 and decided to combine their background: Filip – classic cars restoration, and Krystian – 3D engineering.

Since there was no guarantee that the idea was viable and profitable, they decided to test it on one of Filip’s Mercedes SL500. Their first pick was the sun visor trim cover, which was a problematic and often breaking part because of its imperfect geometry and high sun exposure. The part was reengineered and reinforced, never to fail again, and 3D printed afterward. Eventually, many other SL owners quickly recognized the quality and requested multiple pieces for their cars.

Lear more

Why Lisa PRO is perfect for final parts?

Problem

Almost no manufacturers want to focus on classic car spare parts because the production volumes are too low. No manufacturing technology is cost-effective enough to bridge that gap, except 3D printing. This was an excellent opportunity for all classic car lovers like them.

Finding new parts suitable for 3D printing quickly became their hobby and mission. There are plenty of parts in different cars which are either difficult to find on the aftermarket or costly.

This is precisely the scenario that happened to the classic Mercedes owner who needed to replace the power steering fluid cap, which is not available on the market. He decided to contact Krystian from OctoClassic to help him in solving this problem.

Solution

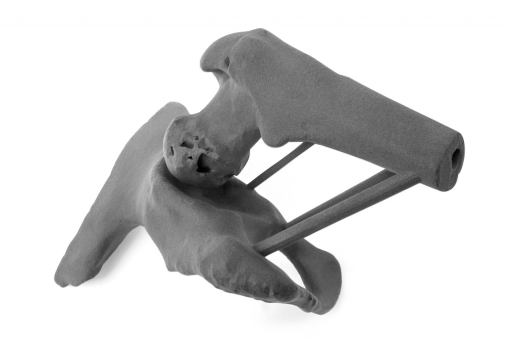

OctoClassic engineers carefully measured and analyzed the power steering fluid cap’s geometry with their industrial 3D scanning equipment, and the team of 3D modeling engineers created a precise virtual representation of the original part using professional 3D CAD software.

The original part was redesigned to fit modern nuts and printed in the highest quality possible using a Lisa PRO 3D printer.

They decided to use polypropylene to produce the spare part because it guaranteed the final piece’s high durability. The quick printing process and mounting of the spare part allowed its owner to enjoy the ride again just a few days after the component malfunction occurred.

Krystian and Filip continue their work in supplying 3D printed replacement parts for classic cars, and their passion for keeping their customers’ vehicles in good shape is constantly growing.

By involving the Lisa PRO for their projects, they can use different powder materials precisely dedicated to specific part requirements.

Visit our customer’s website:

-

showing a design concept redesign as a method to create reliable parts

-

prototype new products creating parts not available on the market

-

perform functional powder materials precisely dedicated to the specific requirements of the parts