Sinterit Studio is now available for Lisa X

One of the most significant parts of Sinterit’s SLS 3D printing solution, the software called Sinterit Studio, was just upgraded to serve the newest compact SLS 3D printer – Lisa X.

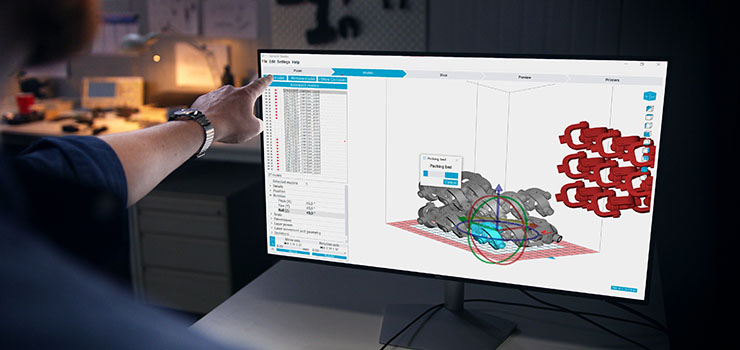

Sinterit Studio, the in-house developed software, is an essential part of the SLS 3D printing process. It guides the user quickly through the whole job preparation, build, slice, upload, to fully control the printing process. Powerful features, like autonesting, automatically and optimally distribute the desired elements within the printer’s chamber. The software checks collisions and helps track the progress.

The slicer displays the printer’s parameters and available materials. But most of all, Sinterit Studio gives access to over 32 parameters that could be controlled, starting from printing temperature, warmup and cooldown, laser power and movement, model scale, and more.

Adding Lisa X to Sinterit Studio was an obvious move as the company is ready to deliver the first orders of the newly launched compact SLS 3D printer. No matter if it will be the first, or additional Sinterit printer in the client’s lab, after updating Sinterit Studio, thousands of Sinterit’s users around the world will gain access to the fastest compact printer in Sinterit’s offer.

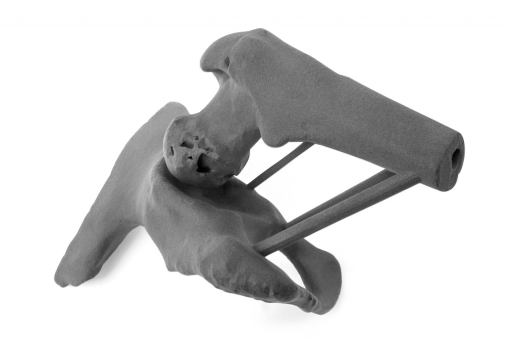

Lisa X has a build speed of up to 14 mm/h and is ready to print a full bed of the most complicated shapes in 34 hours. Large printing volume (180 x 130 x 330 mm), nine available materials, from ultra-durable, through flexible to more specialized ones like Carbon Fiber or ESC powders. Lisa X, the product of the most experienced company on the compact SLS 3D printing market, keeps the best printing quality known from its predecessors. The open environment, with the availability to change 32 printing parameters, makes it the desired choice for universities, research, and development labs, but also for all of the users who would like to use external materials.